Blog entry by rweret erwert

บุคคลทั่วไป

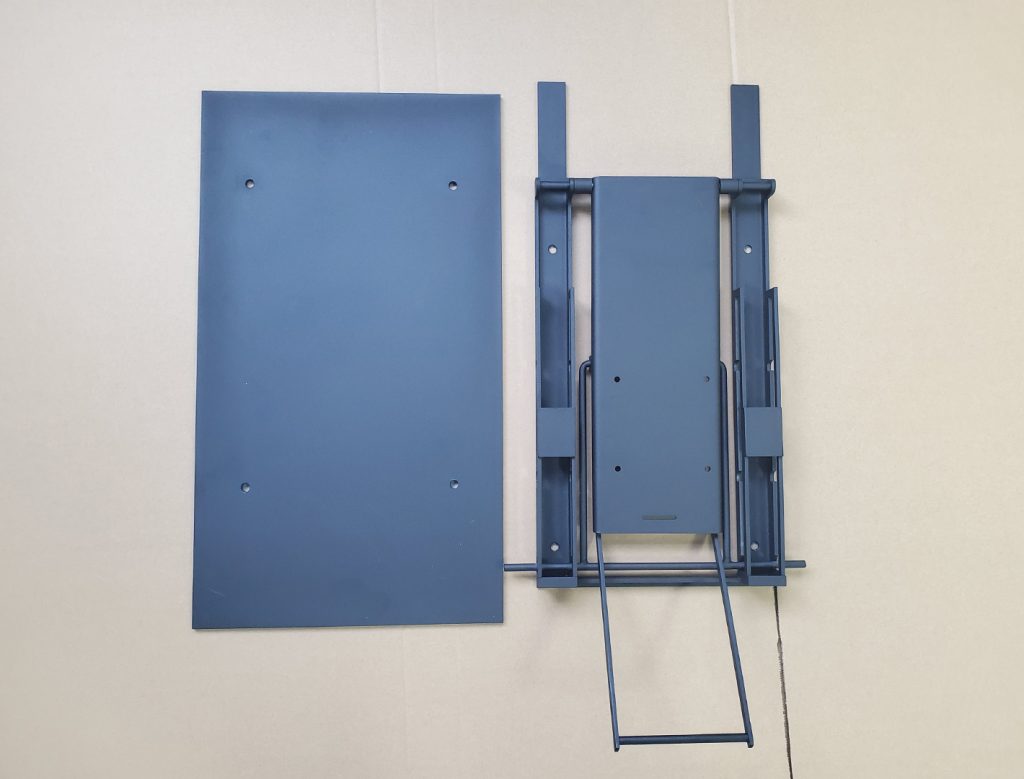

heet metal fabrication is a set of manufacturing processes used to turn sheet metal stock into functional parts. The sheet metal is usually between 0.006 and 0.25 inches (0.015 and 0.635 centimeters) thick.

There are several processes that fall under the umbrella of ‘sheet metal fabrication’. These include cutting, bending and punching, and can be used either in tandem or individually.

Sheet metal fabrication can be used to create either functional prototypes or end-use parts, but end-use sheet metal parts generally require a finishing process before they are ready for market.

Upload your parts to get a free, instant quote

Sheet Metal FAQ

Do I need laser cutting, water jet cutting or plasma cutting?

Does it cost more to use multiple sheet metal forming processes?

Is there a minimum order quantity?